Did you know that you can build a powerful linear actuator single-handedly by using a servo drive and a bunch of other tools that will cost you no more than a couple tens of dollars? Let’s find out all about it in this feature!

What You’ll need

In the process, you’ll need a servo drive, fully outwashed glue-stick, slider-type variable resistor (potentiometer), patch cord category 5, toolset, duct tape, steel ruler, soldering iron, and epoxy adhesive.

Commencing construction

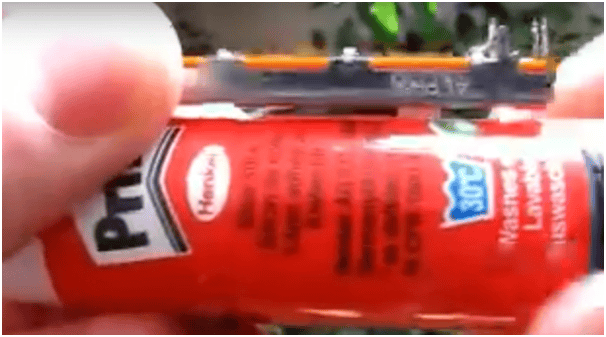

For starters, lock the glue-stick to a steel ruler. Simply stick it with a duct tape (leave the middle of the stick tape-free).

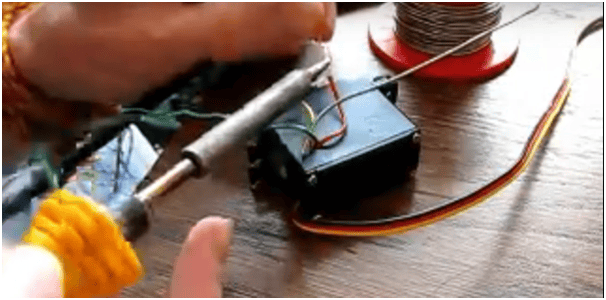

Heat up a solderer. Measure the length of a groove in the slider-type resistor. Make a vertical aperture of the same length in the sick body.

Cut off the bottom part of the transformed stick with a solderer to fully uncover its bottom.

Glue the stick with the help of epoxy adhesive bottom to the motion element situated in the servo bolt (easily removable).

A slider from inside the glue bottle can be used as the main slider in the actuator (an element holding the adhesive composition). Take it out of the stick and make there an aperture corresponding in size with the resistor slider.

Then, the element must be screwed back in inside the stick (in such a manner so that an aperture is seen through the vertical slot made previously). Now, put the slider in a newly formed aperture and lock the resistor to the stick.

Put the stick together with the motion element onto the servo. You’ll need to solder servo wires with resistor wires. You’ll also need to solder a category 5 patch cord to the servo which will be connected to the power supply later.

That’s it, the device is all set! Now test its performance and check whether wires between resistor and servo are soldered in a right order. In a positive case, lock the resistor onto the stick more tightly (e.g. with the help of adhesive tape).

Conclusion

So, you can create a small but performing linear actuator yourself. It would take about half an hour of your time and will cost you no more than 15-20 bucks (the most expensive part here is servo). On the other hand, if you are looking for a device for a constant use that would be highly reliable and sturdy, you’d better pick from the models produced by specialized manufacturers. Take a look at the widest assortment of linear actuators and accessories for them at our website.

Newbie here. Sorry for the off topic but I’ve been trying for a few days now to understand the difference between a rheostat and a potentiometer but to no avail. I’ve tried to read about it on Wikipedia and even this article with a video about rheostats but they don’t really explain the difference in layman’s terms.. Too many long words 🙂 Could somebody here please explain the difference like I’m 5? Any and all help will be much appreciated. Thanks in advance