In Satisfactory 1.0, the challenge of improving and fine-tuning production processes is an ongoing and engaging task for experienced players.

One such interesting project is exploring and building the Biochemical Sculptor.

This guide will take a deep dive into the step-by-step approach of making this component, looking at the key recipes, and comparing the best and worst methods for maximum efficiency.

What is a Biochemical Sculptor?

The Biochemical Sculptor is an advanced item in Satisfactory, mainly used in the complex production chains of the game.

This component plays a crucial role in phase five of the Space Elevator parts, requiring careful planning and a good understanding of the game mechanics to produce efficiently.

Why focus on the Biochemical Sculptor?

Complex Production Chains: The Biochemical Sculptor’s assembly line needs many intermediate and raw materials, offering a chance to improve and understand the production system deeply.

Resource Management: Efficient production of the Biochemical Sculptor helps players become skilled at managing the wide range of resources available, from raw ores to complex manufacturing systems.

Main Steps and Required Recipes

Foundation Setup: Material Needs

Making the Biochemical Sculptor requires a wide range of materials. The key ingredients include:

Assembly Director Systems: Essential for organizing production processes.

Fixitronics: Important for advanced manufacturing operations.

Water: Used in various refining processes.

Detailed Breakdown of Essential Components:

Computers and Adaptive Control Units

To make a biochemical sculpture, you must first get essential components like computers and adaptive control units. Here’s a detailed breakdown, including the resource allocation and processing.

Adaptive Control Units:

- Resources for producing 0.5 Adaptive Control Units:

- Criterium: 6 units

- Copper Ore: 6.2 units

- Raw Quartz: 9.3 units

- Iron Ingots: 73.5 units (from combining multiple processes)

- Limestone: 18.2 units

- Water: 88.4 units

Note: These values are for 0.5 units. For more accurate calculations, especially when aiming to produce more units, double these values or adjust as needed.

Computers:

Making Computers involves these key materials:

- Rubber: 6 units for optimal flexibility in manufacturing.

- Quick Wire: 14 units, vital for electrical components.

- Circuit Boards: 4 units, which require both copper and quartz.

- Water: Necessary for cooling and processing. Requires 12 units.

Intermediate Materials Production

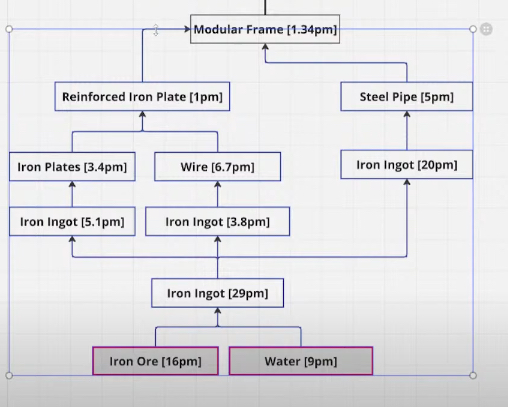

The intermediate materials needed, such as Circuit Boards, Modular Frames, etc., are split into smaller, manageable assembly steps, summarized as:

- Iron Ingot Production: Central to many components.

- Quick Wire: Made from Criterium, used in several recipes.

- Steel Pipes and Encased Beams: Essential for the structural frames and support.

Advanced Manufacturing: Higher Order Materials

As shown in this post, producing the Biochemical Sculptor efficiently involves continuous integration of multiple production lines, such as assembling Robot Assemblies and Quantum Computer Recipes:

Fixitron

Fixitronics or “Fixit トリオン” is a higher-order material made from Criterium Ingots and Reanimated Sam. These can be summarized as follows:

- Reanimated Sam: 80 units per minute.

- Criterium Ingots: 54 units per minute.

- Water: 54 units per minute.

Production Layout: Efficiency and Integration

An efficient production layout centralizes the raw material feeders, like Iron Ore, Crude Oil, and Limestone, to various processing units.

Then, moving these intermediate products such as Rubber and Quick Wire to assembly factories reduces transportation and increases production efficiency.

Challenges and Solutions

Achieving an efficient production system isn’t without challenges:

Resource Management: Balancing the input of basic resources to minimize bottlenecks.

Energy Consumption: High-output manufacturing plants have significant power needs. Ensuring adequate power supply is crucial.

Space Management: Strategically placing production units to maximize output while minimizing the space ensures streamlined operations.

Real-World Application in Satisfactory

The post provides an excellent demonstration of these principles in action. Here’s an overview of key insights:

- Resource Gathering: Methods to efficiently gather and process essential materials.

- Layout Planning: Visual depiction of a well-structured production setup.

- Adaptive Changes: Implementing changes based on observed inefficiencies.

- Viewer Interaction: Engaging with other players to discuss potential improvements and answer common questions.

Conclusion

The process of creating the Biochemical Sculptor in Satisfactory 1.0 is both a challenge and an opportunity to deepen your understanding of efficient manufacturing systems within the game.

You can gain significant insights into learning this complex yet rewarding task by exploring the essential recipes, breaking down material requirements, and optimizing production layouts as showcased in this post.

Are you ready to take on this challenge? So, what are you waiting for? Get into playing the Satisfactory world, use the steps outlined in this guide, and improve your production lines like never before.